Increasing performance and capacity automatically

High-bay warehouses have a particularly high degree of space utilization. They offer maximum capacity for pallets and other loading devices in a small footprint. Optimized, software-controlled material flows ensure error-free, high handling performance in the smallest of spaces. Depending on the company profile, different storage types are suitable for fast, precise and cost-effective storage. And to increase goods turnover and delivery readiness, even with low staffing levels. Production becomes more flexible. The storage system is future-proof. It's reliable, adaptable, and grows with your business.

Fully automated storage systems are integrated into existing warehouses. Or built in a self-supporting silo design as an economical alternative to manual, forklift-operated warehouses. Our storage types are designed with two main focuses: speed and capacity. Here are the three basic types.

The structure

In a double-deep storage system, a rack compartment is designed to hold two load units one behind the other. As a result, only every second article can be accessed directly, but with greater space utilization than in single-deep storage. With a high variety of items, intelligent rearrangement ensures good access frequency. Telescopic forklifts are often used here as well.

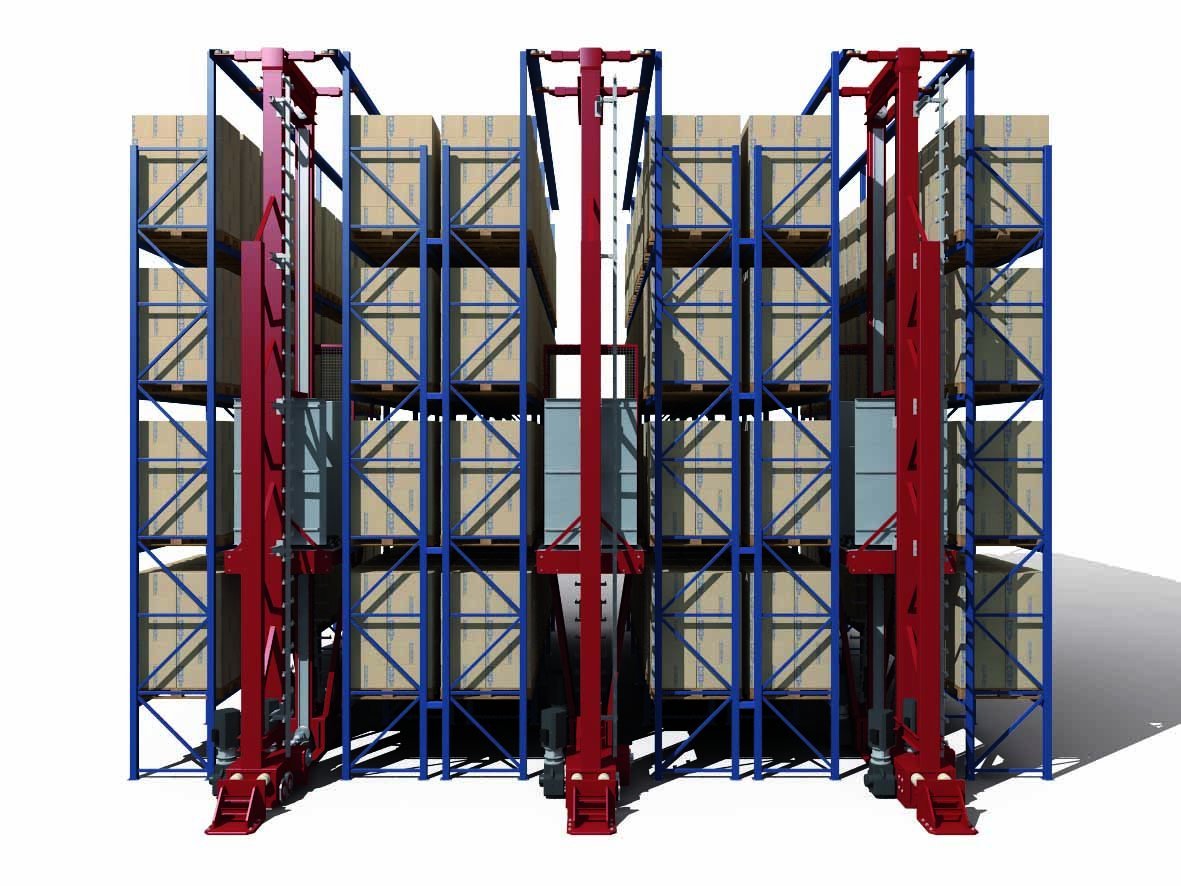

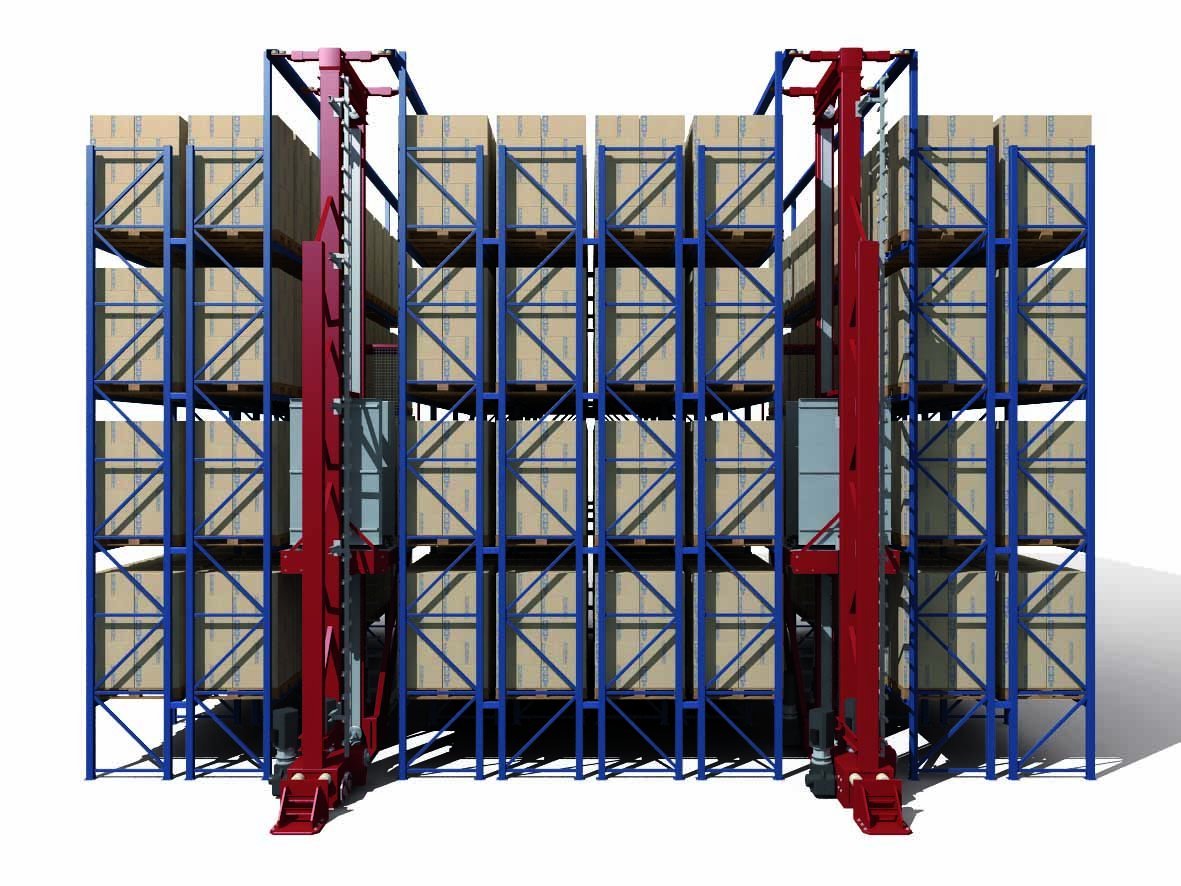

The structure

In a Satellite® warehouse, the Satellite® load handling device stores items at multiple depths and is gentle on the material. Depending on requirements, one storage and retrieval machine may be sufficient to serve the entire warehouse, but it may not have direct access to all articles. In the case of multiple aisles, the flexible Westfalia center block is created without a central separation of the storage aisles. This means that a single SRM unit can serve all aisles in the center block, for example during maintenance. Goods are stored at high density for maximum capacity. Sequencing buffers are ideal for high variety and high turnover.

Automate deep-freeze storage with energy efficiency

Our automated storage systems are designed for ultra-low temperatures down to -35°C. They also offer high performance and availability as chilled and deep-freeze warehouses. Satellite technology enables extremely compact warehouses. This reduces the space to be cooled and the energy costs per pallet location.

Storage solutions for many industries

How do our technologies and systems make a difference in your industry? For more than 50 years, we have been working closely with our customers to develop customized solutions. Learn more about our projects in the food, beverage, corrugated cardboard and packaging industries or contact us for references in other industries.