High-bay warehouse with telescopic forks: fast and flexible

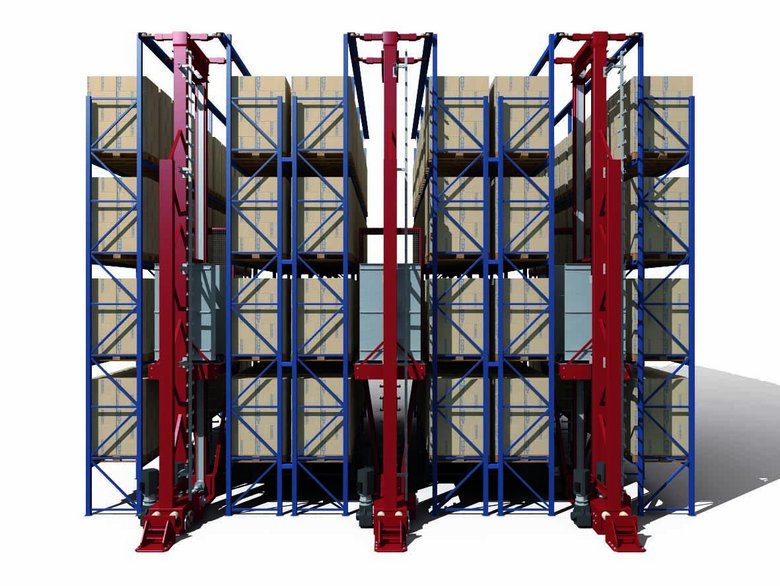

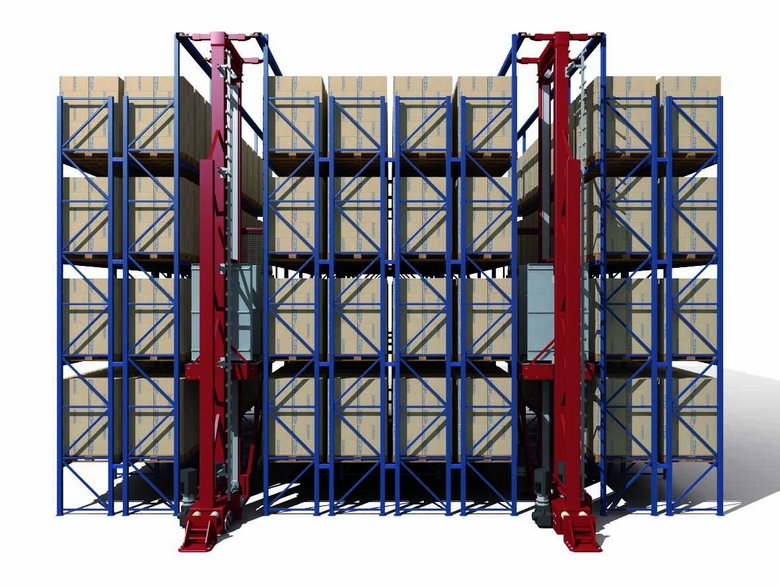

Those who need direct access to a wide range of products, have tightly scheduled storage and retrieval deadlines, and high inventory turnover rates often rely on single-deep and double-deep storage systems. They have one or more storage aisles. Each aisle is assigned single- or double-deep racking compartments on both sides. To access them particularly quickly storage and retrieval machines are usually equipped with telescopic forks.

Such automated storage systems offer the optimal compromise of high access frequency at a medium storage density. Compared to compact warehouses with Satellite®, space required for the storage and retrieval machine aisles is eliminated. Compared to manual warehouse processes, process errors are minimized, and throughput is increased - with a moderate vehicle fleet and stable staffing levels.

The system speeds up shipping and picking. It relieves staff and enables higher production speeds and warehouse capacity, even in phases of a lack of skilled workers. Forklift traffic and accident risks are reduced.

Fast warehouse on a small space

Telescopic forks are the established standard in warehouse logistics, including forklifts and autonomous industrial trucks. But also in many automated storage systems. Their decisive advantage is that the storage and retrieval machines can access storage heights of more than 40 meters. This saves space and makes it possible to adapt spacious warehouses to tight cutting requirements.

Telescopic fork storage systems are also exciting for intermediate storage and production buffers because they enable replenishment along production lines as needed or accommodate goods for delayed orders. This reduces expensive setup times. Software such as our Savanna.NET® Warehouse Execution System manages the warehouse and creates seamless data transparency.

Seamlessly linked to ERP systems, it offers the potential for ongoing process optimization. It assigns warehouse parameters to goods and load units even before they are dispatched, e.g., retrieval date or reservation. This saves time spent searching for storage locations or goods in manual warehouses.

Load handling device telescopic fork

Telescopic forks with two prongs move and store palletized or non-palletized load units weighing up to 1,500 kg quickly, safely, and gently into single-deep or double-deep rack compartments. We equip storage and retrieval machines, transfer cars or vertical conveyors with durable, robust telescopic technology for the required load.

Depending on requirements, we offer standard or customized designs: e.g., for deep-freeze temperatures, with anti-slip equipment and other optional features, as well as with optimized installation heights. Height grids in the storage rack make depth supports superfluous. Telescopic forks are particularly suitable for single- and double-deep storage but are also used in other applications.

Robust and insensitive telescopic technology ensures high load capacity and durability of the storage and logistics systems. Various loads, pallets, other loading aids, goods and formats are transported efficiently and reliably by the telescopic forks we use.

We work together with quality suppliers. They ensure high functionality, precision, and stability for fast and at the same time gentle pallet and goods handling.

Our warehouses do not come off the shelf but from a single source. We have been finding the perfect individual warehouse layouts and load handling devices for many industries since 1971. Learn more about the interaction of our technologies in the food, beverage, corrugated cardboard and packaging industries or contact us for references from other industries.