Borgholzhausen/Stuttgart, January 11, 2024 – From March 19 to 21, 2024, intralogistics expert Westfalia Technologies GmbH & Co. KG will be presenting its latest bestseller for the first time at LogiMAT in Stuttgart: its compact single-mast storage and retrieval machine. With this technology, Westfalia is also paving the way for small and medium-sized companies into process automation. This is because it pays off from just a few storage locations and can also be integrated into existing warehouses.

As a specialist in automation along the entire supply chain, the Westfalia Group designs, implements and modernizes automated warehouse and logistics systems worldwide with the highest levels of efficiency and reliability. Westfalia is particularly well known for automated high-bay warehouses with heights of up to 40 meters and several thousand high-density storage locations with two-mast storage and retrieval machines (SRMs). With its single-mast storage and retrieval machine, Westfalia also offers small and medium-sized companies an automation solution to remain fit for the future, optimize processes and make warehousing more sustainable.

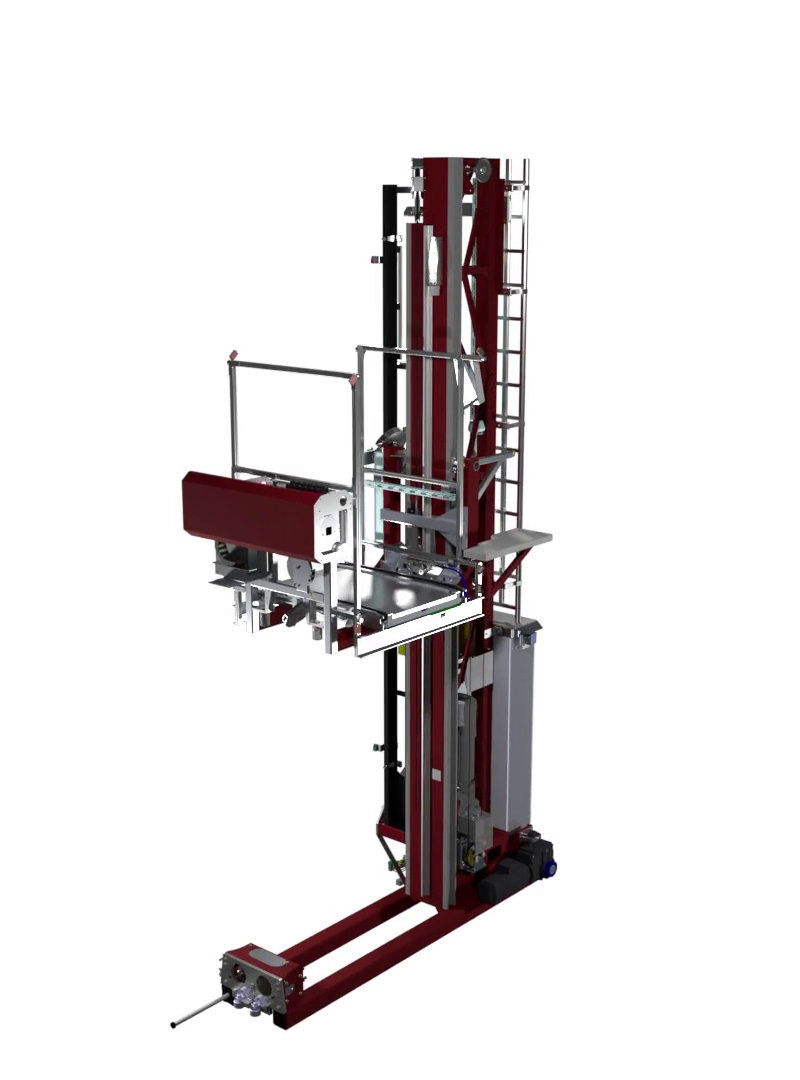

New builds and extensions are only one option for cost-effective intralogistics automation. Westfalia's single-mast SRM also applies to existing buildings: Thanks to its low height of 6 to a maximum of 18 meters, the storage and retrieval machine can be easily integrated into existing warehouses and racking structures, as it takes up very little space while acting on the existing structure with minimal load input. Westfalia's single-mast SRM also impresses with its very small approach dimensions for maximum warehouse utilization. With these advantages, the available space can be optimally utilized.

With fast telescopic forks for high access frequencies or with the Westfalia Satellite® load handling device for maximum storage density, high-performance warehouses are created with maximum capacity on a minimum footprint. Depending on requirements, multi-deep storage blocks can even be served from a single, narrow storage aisle with just one storage and retrieval machine.

Westfalia's single-mast SRM also scores with its good accessibility and ensures user-friendly operation with an optimized operating and maintenance concept. Another positive aspect: operating costs are reduced thanks to the very low weight of the machine and lower energy consumption.

At Stand 1C20 in Hall 1, visitors can find out more about the compact single-mast storage and retrieval machine and see for themselves the wide range of Westfalia solutions for automating and optimizing warehouse logistics.

Shaping the future with technologies

Since 1971, traditional craftsmanship has met high-tech at Westfalia Technologies: As a specialist for automation along the entire supply chain, the Westfalia Group designs, implements and modernizes automated warehouse and logistics systems of the highest efficiency and reliability worldwide.

With the key technologies Satellite® and telescopic forks as well as particularly gentle pallet handling, Westfalia Technologies is a general contractor specializing in single and double-deep storage systems as well as compact storage systems for automated multi-deep storage: from consulting and on-time implementation to comprehensive 24/7 services and service packages, IT/PLC services and support, safety training, rack inspections and maintenance as well as parts management.

Westfalia Technologies develops, manufactures and implements storage and retrieval machines, conveyor technology including PLC control and the powerful Savanna.NET® warehouse execution system, which combines software functions for warehouse management and material flow control. As part of the WORTMANN Group, the intralogistics automation specialist offers the complete TERRA-IT infrastructure.