Pepsi Bottling Group (PBG) is the largest manufacturer, seller and distributor of Pepsi beverages with more than 100 plants and 545 distribution centers worldwide. Based in Tampa, Florida, PBG was faced with the task of maximizing storage space and designing intralogistics for peak times. Production had to keep up with increasing demand.

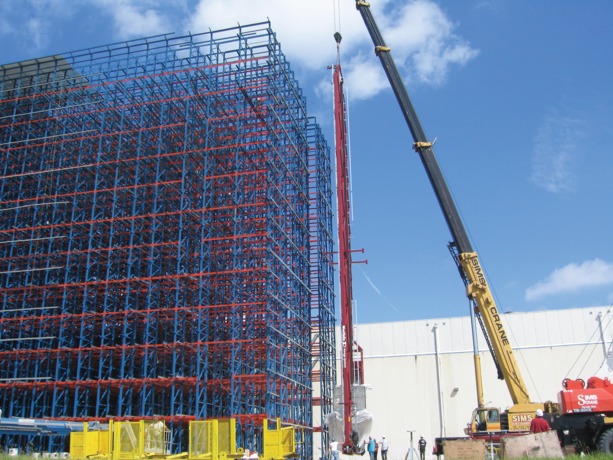

Westfalia automated the system with a single-aisle warehouse with two Satellites with two automated storage / retrieval machines (AS/RM) and 12,000 rack positions on 13 levels. The storage system handles peak production times from the filling plant as a buffer. It also helps to prepare differently picked pallets for dispatch to customers.

Warehouse Execution System for the entire flow of goods

Westfalia's Savanna.NET® Warehouse Execution System (WES) manages and controls the products flow throughout the plant, from receiving to dispatch – a complex system with full layer and mixed layer palletizing from their own production and from outside bottling operations. It is fully integrated with PBG's EPR and WMS, tracking and managing all goods.

In addition to the two AS/RM, which transport load units in pairs to save energy, Savanna.NET® controls conveyor systems for pallets and boxes, five KUKA robots for layer picking and palletizing, an pallet squaring station and the stretching and and labelling for load units. The compact storage system requires only 30 percent of conventional equipment, reducing energy, labor and product waste costs. As such, it contributes significantly to the Pepsi Beverage Company's "Going Green" strategy.

Here are some more references that might be of interest to you:

beckers bester GmbH

RAMSEIER Suisse AG

Marketing

Marketing & Kommunikation

Ask our sales team

Find answers to your automated warehouse logistics questions and learn more about our technologies and systems. By e-mail via the contact form or by phone. We are looking forward to your request!