At a glance:

> Flexible design that provides robust inventory management, order

management and fulfilment, and direction of automated equipment.

> Interfacing with virtually any host system and a variety of interfaces.

> Support for both conventional and automated warehouses:

automation is not necessary to take full advantage of the

Savanna.NET® functionality.

> User-friendly interface that supports intuitive operation.

> Sophisticated storage and retrieval algorithms for maximum

warehouse space utilisation.

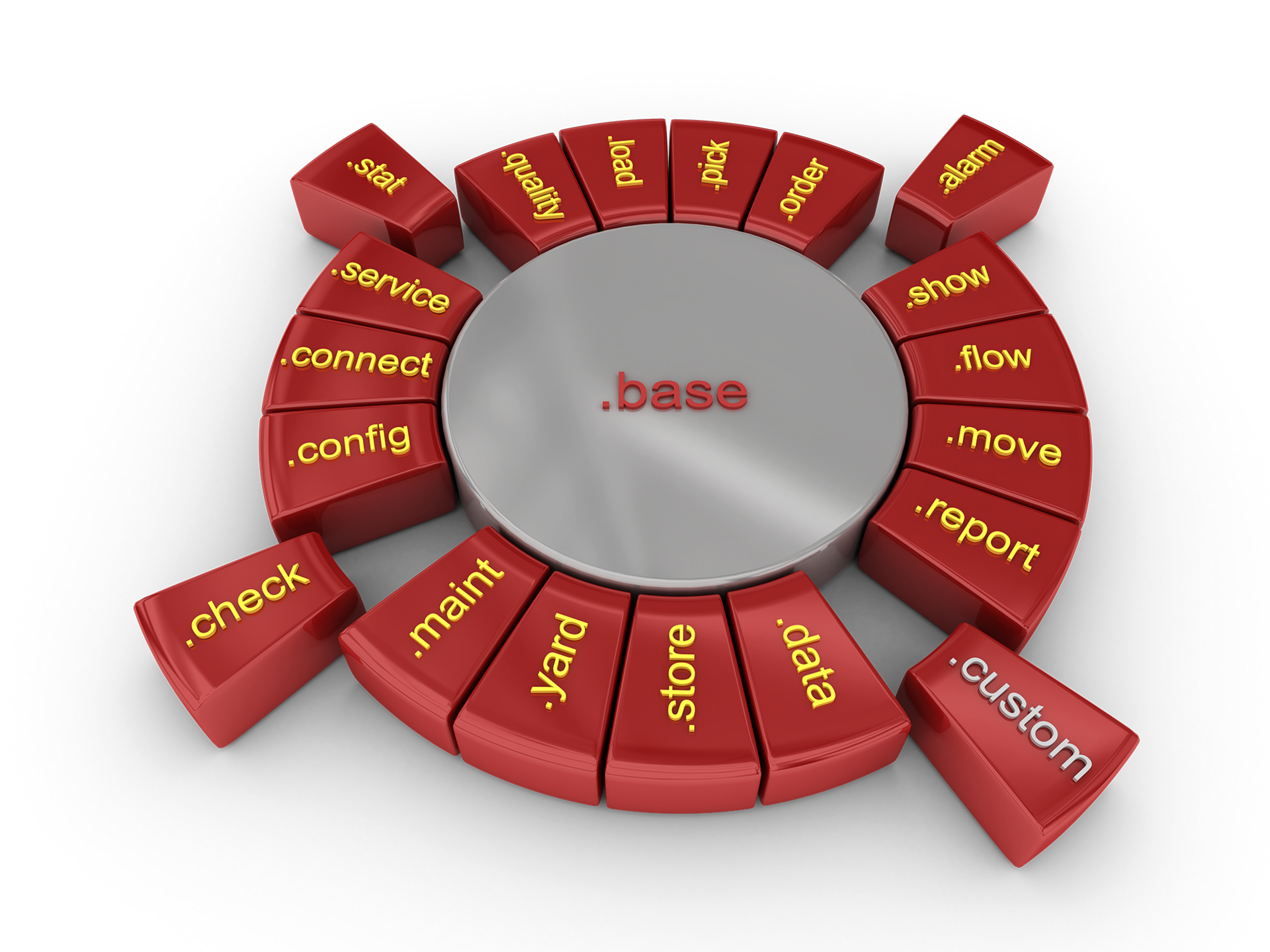

The Savanna.NET® platform can manage the entire warehouse process, or only the aspects of your operation that require more sophisticated and accurate measurement and/or management. A key benefit here is scalability. If the volume or geographic coverage of your business expands, Savanna simply grows with it. Its functionality is also easily enhanced by client-driven customisations.

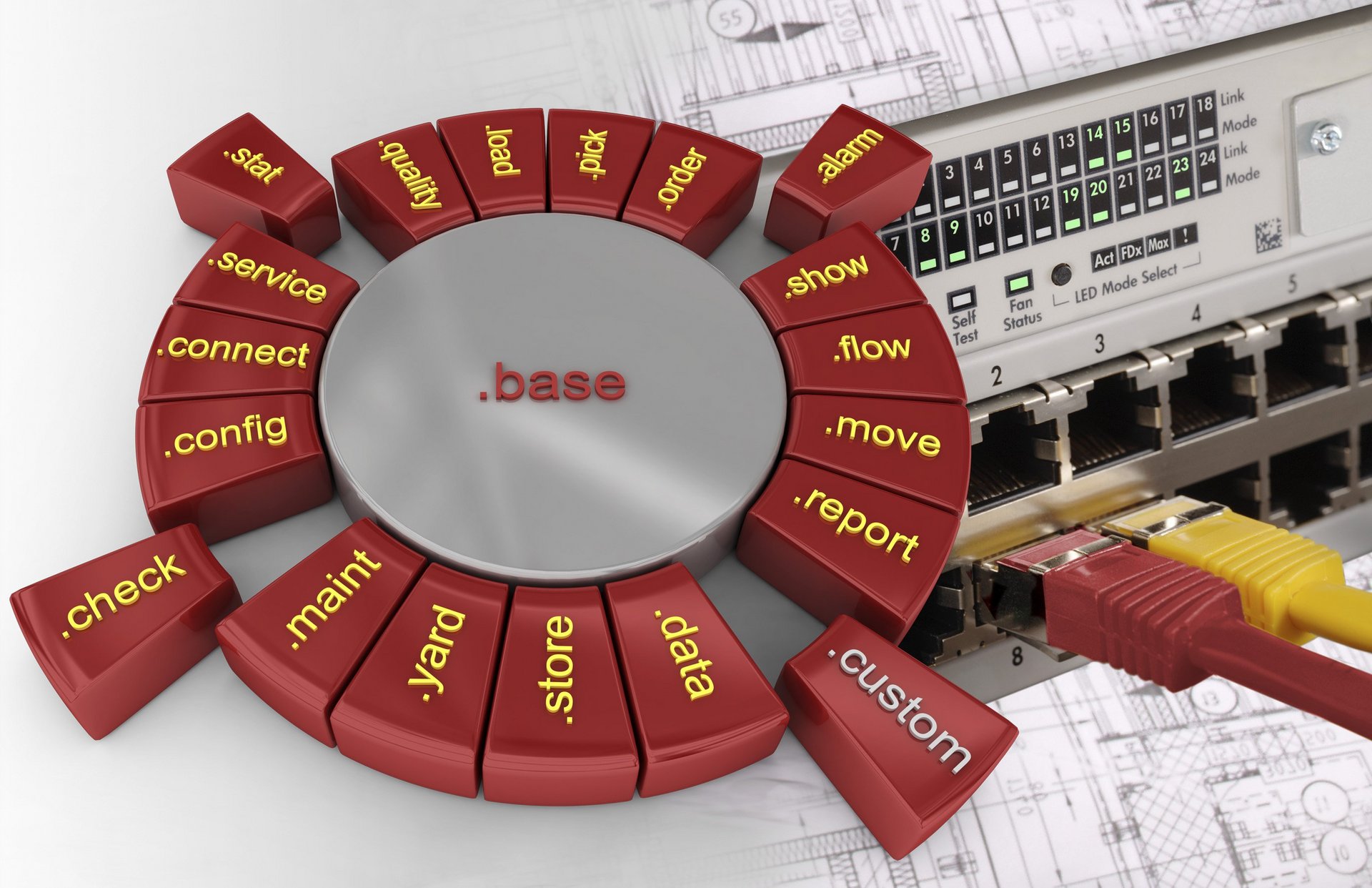

Savanna.NET® has been conceived with flexibility in mind, to accommodate virtually any racking system, material handling equipment, aisle layout and ceiling height. The Savanna.NET® Warehouse Execution System can bundle existing individual solutions within one piece of software. The flexibility of Savanna.NET® is the foundation that allows for various IT-side deployment options.

For those with an existing warehouse management system looking to introduce a material flow control system to assist in automation, it is worth opting for Savanna.NET®. This allows your company to continue using your familiar warehouse management system, integrate it with the WES and then enable only the material flow control functionality.

Alternatively, if an organisation has not yet introduced automation warranting a material flow control system, it can still implement a warehouse management system, only utilise the warehouse management capabilities, and then ‘turn on’ the material flow control functionality when needed. This allows operators to utilise a familiar user interface, reducing training time and shortening the system startup duration.