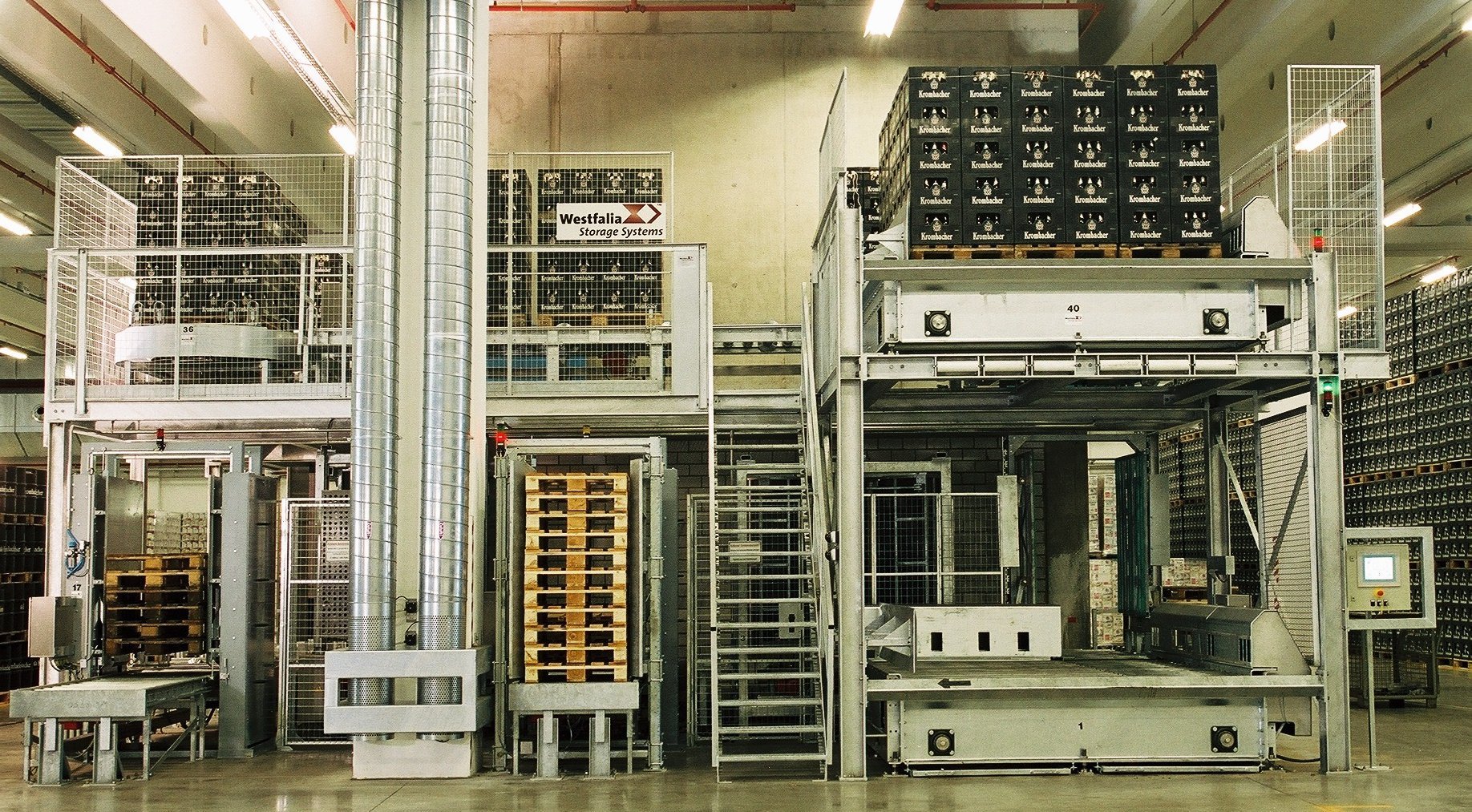

Partial or full automation of warehouse logistics is an ambitious process. It requires investment. In competent logistics planning, in target-oriented project management of the short wires. And in quality components. As a well-connected manufacturer of many key components of automated high-bay warehouses with more than 50 years of experience in planning, design, and project management, we have everything you need to automate your warehouse logistics.