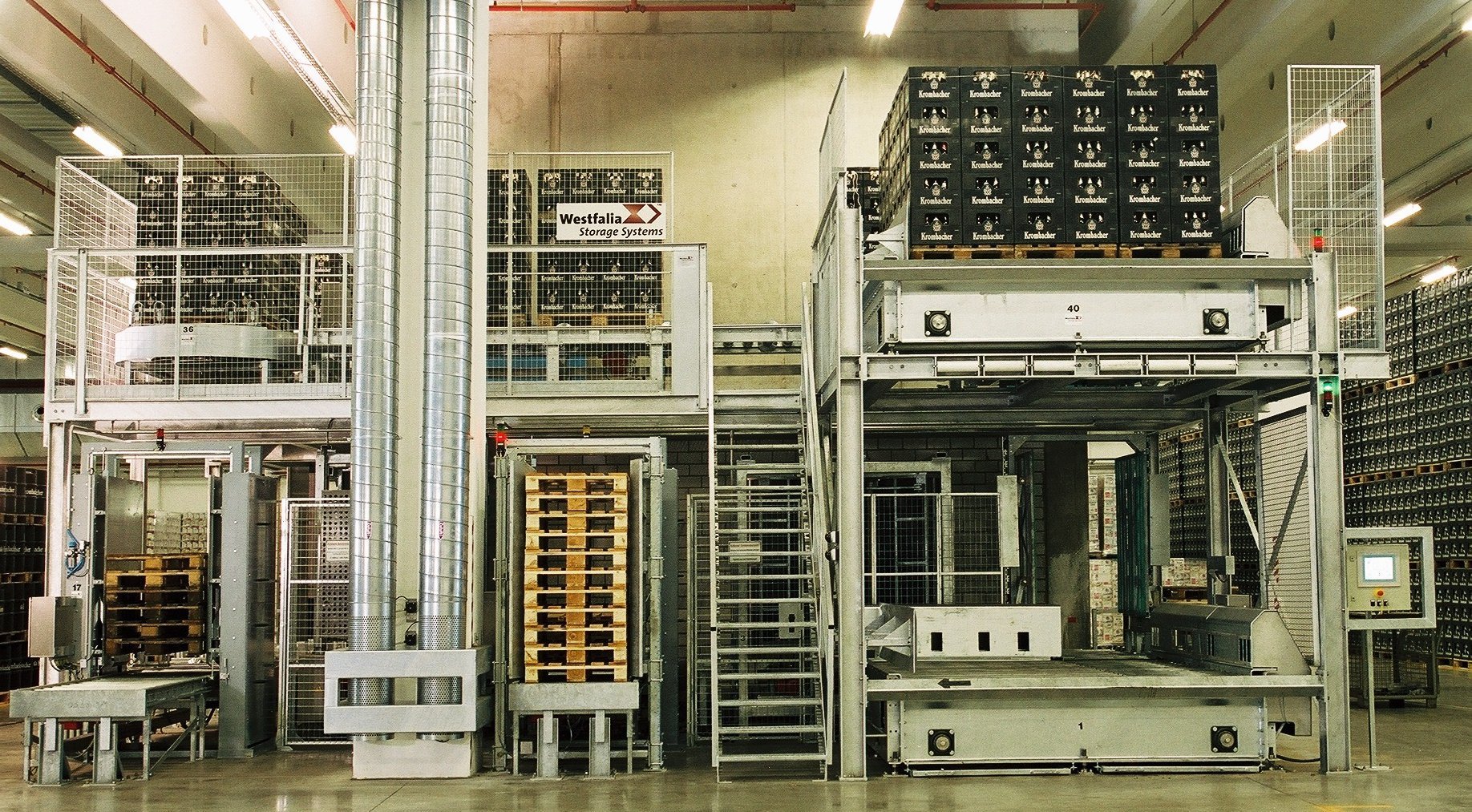

If a high-bay warehouse with high-performance storage and retrieval machines is the heart of automated warehouse logistics, the surrounding conveyor lines and interfaces are its veins. This is where there are many opportunities for optimization to make intralogistics processes even faster, safer, and more reliable. Automated software-controlled conveyor technology intelligently links production, storage, order picking, and loading zones into an effective overall system.

Complexity tailored to existing properties

With standardized or individually designed conveyor systems, we are able to condense the most complex material paths into a small space. In exactly the space available to you as an entrepreneur. These conveyor systems send your goods gently and quickly from A to B. Modern inspection stations at neuralgic points relieve your personnel and prevent malfunctions.

Our engineers plan your custom-fit warehouse into your existing real estate. As with our storage and retrieval systems equipped with Satellite® or telescopic forks, we test all key units extensively. Only then do they leave our factory and go into operation at your site.

We plan and implement with an open mind to the future. The partially automated or fully automated logistics systems can be expanded, converted and thus further areas automated whenever this makes economic sense for your company. Our conveyor technology grows with you. And nestles organically into the existing infrastructure.

Our conveyor technology picks up your industry. As standard, it is designed for crosswise or lengthwise transport of Euro pallets according to DIN EN 13698-1, industrial pallets according to DIN EN 13698-2 or plastic pallets. But we also customize our systems for special pallets, other loading aids or palletless transport.

Our conveyor systems for pallets, boxes or other loading aids are flexible and modular. They are adapted to local conditions, with different construction heights and height-adjustable foot constructions. In the layout and design, we also pay attention to optimum accessibility for maintenance and ground clearance for cleaning.

Best connections – at the plant, on the market

Conveyor systems consist of thousands of individual units. With our more than 50 years of experience in many industries, through good market networking and short supply chains, we are an optimal system supplier even in global bottlenecks and under difficult conditions. We supply warehouse technology and materials handling equipment including PLC systems. And program the comprehensive Warehouse Execution System Savanna.NET® at our headquarters.

"Everything from a single source" is more than ever our claim as a general contractor. Take advantage of our know-how, from detailed consulting and planning to commissioning and comprehensive service, so that the automation of your material routes quickly becomes a reality. We look forward to your inquiry and will be happy to advise you.