Industrial space is limited. When companies expand, intralogistics also increase and become more complex. Semi-automated and fully automated rack storage systems make it possible to grow in height instead of length. Even far beyond the warehouse heights that manual forklifts or automatic industrial trucks can reach.

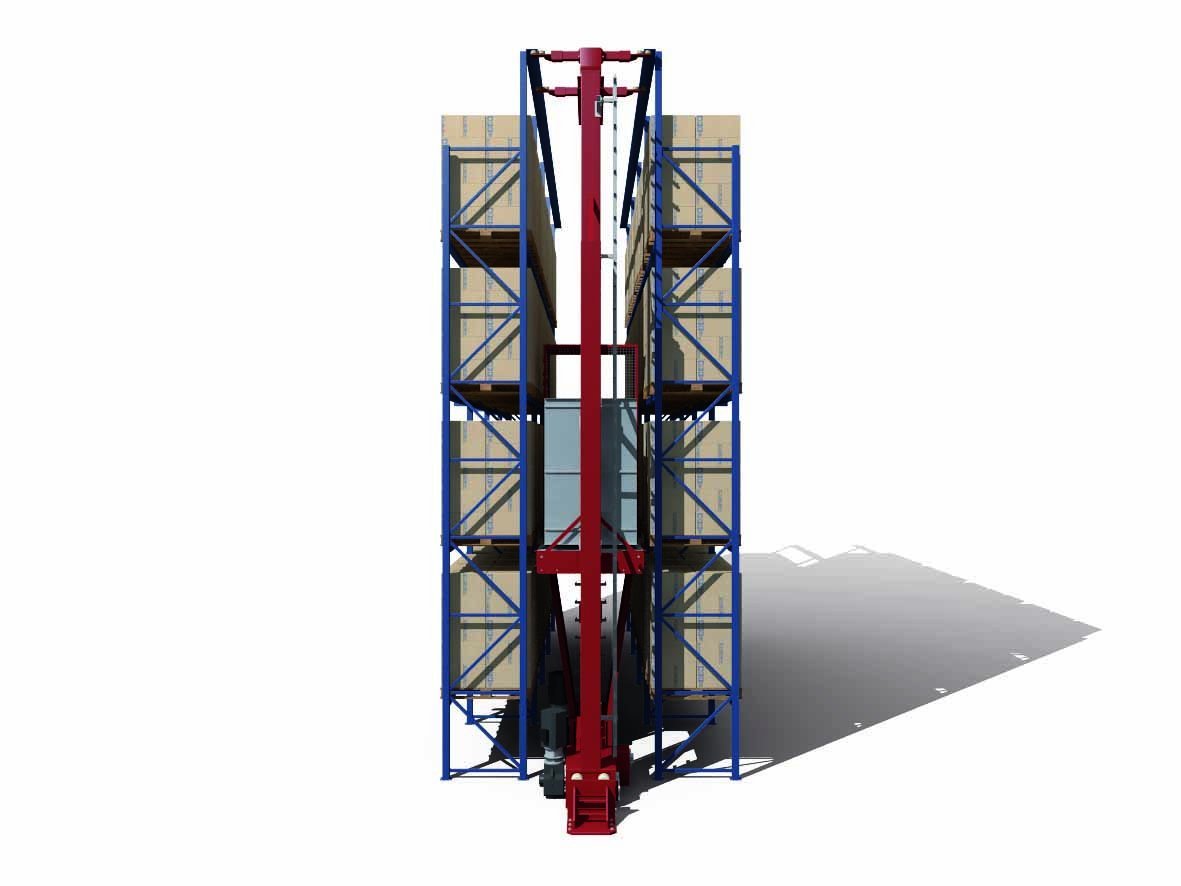

Our storage and retrieval machines (SRMs) enable high-bay warehouses of 40 meters in height and more. Our patented Satellite® load handling device maximizes storage density to enormously deep storage channels with special storage profiles for multi-deep storage that is particularly gentle on pallets and materials. SRMs equipped with telescopic forks achieve higher access frequencies to single-deep or double-deep rack, compartments.

Wherever the right balance between throughput, capacity and compactness lies for your business: We specialize in space-saving automated high-bay warehouses in silo design or in new as well as existing self-supporting buildings.

Storage and retrieval machines: In-house production, highly reliable

Our storage and retrieval machines are reliable - and this is due to our system support over decades. As a manufacturer, we make sure of this: because we manufacture the storage and retrieval machines and many key technologies at our headquarters in our own factory. There, we also operate a test center for key aggregates so that our concept quickly becomes reality for the customer.

So, before the heaviest pieces of our storage systems leave our factory, they are put through their paces. We send only the highest quality by heavy transport on the journey. Then we install them on site at your company and put them into operation. You receive the entire know-how, from planning to commissioning to comprehensive service, from a single source - just like your storage and retrieval systems.

Energy-saving, fast and flexible

Depending on the payload, required capacity, formats and storage height, we use single or double mast devices. With our load handling devices, the SRMs are made for high loads and a wide variety of formats. And with the appropriate components, they are designed for normal-temperature, chilled and deep-freeze warehouses. At the same time, they are always at the height of modern storage technologies.

Today, modern drive technology allows energy to be stored or fed back, either into the supply network or into energy storage units directly on the vehicle. Storage capacitors in the DC link provide a large part of the necessary power peaks. Rotational energy and capacitor storage also ensure system operation for drives, motor brakes and controls in the event of power failures.

Modern control systems coordinate the travel and lifting axes of a storage and retrieval machine, coordinating the speed, start and braking times of the axes in an energy-saving and material-saving manner. The axis with the shorter travel distance travels more slowly or starts later. In this way, energy from braking the travel axis or from lowering the load is made available to the other axis. If fewer orders are pending for a vehicle, it travels more slowly overall, thus reducing wear and making it more economical.

Fast and flexible

Westfalia storage and retrieval machines can score with fast approach speeds and maximum accuracy even at great heights. Guided by a powerful Warehouse Execution System, our SRMs find their exact target position via laser distance measurement and camera-based compartment fine positioning.

You push every night shift without additional personnel to automatically provide the truck tours for the next day. You intelligently replenish your high-bay warehouse without interruption - whether single-variety or mixed channel. They ensure replenishment as needed along the production line. All this without human process errors, without unnecessary travel distances, and with a significantly lower risk of accidents.

Modern sensor systems make storage processes more flexible and optimize them. For a long time, signal transmitters in the motors and photoelectric sensors were used for distance measurement and coarse positioning. Today, distance lasers in the chassis are used for coarse positioning and camera-based sensors are used for fine positioning.

This increases storage speed and simplifies the flexible storage of different formats in a single storage channel. Today, camera systems with ring buffer directly on the camera also monitor the processes several times. Images can be called up immediately in the event of a malfunction, faults can be rectified more quickly, and causes can be analyzed more easily.

Down-to-earth or high-flyer?

Those who speak of storage and retrieval machines often mean a chassis with two rollers on a track, to which up to two masts are attached. This stability makes it possible to serve particularly high storage racks. But we have thought even further. The Aviator® hovers over aisles.

This aisle-free SRM variant enables automated high-bay warehouses that can be accessed by people or forklifts at the same time. This enables fundamentally different warehouse layouts with manual and automated areas, serving fire protection or escape route requirements. We will be happy to determine which layout fits your challenges.