Borgholzhausen/Stuttgart, May 3, 2022 - The level-up for efficiency, sustainability and customer satisfaction, from warehouse layout to electromechanics to software: At LogiMAT from May 31 to June 2 in Stuttgart, intralogistics specialist Westfalia Logistics Solutions Europe will be presenting its entire range of technology and services for "turnkey" automated storage systems along the supply chain.

The general contractor provides an overview of all building blocks of successful intralogistics automation and shows how to invest in more efficiency, sustainability and satisfied customers. It has been offering logistics consulting and planning, mechanical engineering, control, software development, installation, modernization, expansion and services from a single source since 1971, manufactures quality "Made in Germany" at its headquarters – its own storage and retrieval machines and conveyor technology including PLC control – and tests its key units in the own test center.

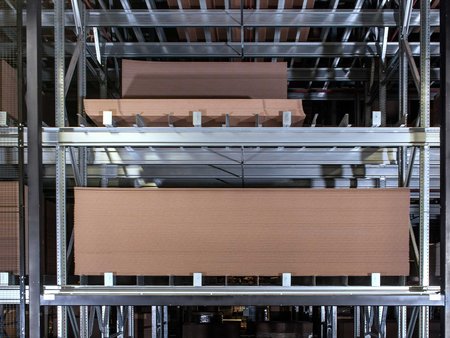

With the patented Satellite® load handling device, Westfalia revolutionized the multi-deep, compact and material-friendly storage of many products, load carriers, high loads and unusual formats.

Software

The high-performance Warehouse Execution System (WES) Savanna.NET®, which Westfalia is showing at LogiMAT, has also been programmed at the headquarters since 2005. It combines the functionalities of a warehouse management system and a material flow control, is easy to implement and grows modularly with the intralogistics. The WES controls and analyzes them completely.

New installations

The first conversation at LogiMAT gives a foretaste of logistics consulting that really helps: Westfalia's experts examine operating processes in detail in order to design, plan and implement tailor-made new warehouse layouts that are economical, future-proof, reliable and highly efficient. The stringent project management with fixed contact persons and more than 50 years of experience in many industries brings strong concepts to the destination on time and on budget.

Modernization

Automating economically often means getting the best out of existing systems. Westfalia has won many long-standing customers with consistent complete modernization in the areas of electromechanics, PLC and software. Whether it's a software upgrade, conversion, extension or retrofit – in Stuttgart, Westfalia is showing companies a key to more performance and flexibility.

Service

Comprehensive 24/7 services, IT/PLC services, training, maintenance, testing and parts management maintain the performance, reliability and safety of automated storage systems. Westfalia uses its experience as an industry insider with a good supplier network. Westfalia systems have been running reliably for decades, and customers always have the system status, repair costs and inspection routines on screen. Visitors to LogiMAT from May 31 to June 2, 2022 can find out how at stand C20 (Hall 1).